Sulthaanan N – 2506565515

Department of Mechanical Engineering, Universitas Indonesia

I. Abstract

This project presents the development of an AI Knowledge Assistant for Force-Flow–Based Design for Additive Manufacturing (DfAM) Optimization. The objective is to support designers in generating lightweight, structurally efficient, and manufacturable components by embedding force-flow reasoning into an AI-assisted decision framework. The methodology combines requirements definition, force-path identification, process-aware design rules, material–process compatibility, and iterative optimization.

Key findings indicate that force-flow–driven reasoning improves structural efficiency by aligning geometry with load transmission, reducing unnecessary material usage, and mitigating anisotropy- and support-related weaknesses inherent to additive manufacturing. The AI framework enhances consistency in early-stage design decisions while remaining adaptable across materials, processes, and loading conditions.

II. Author Declaration

1. Deep Awareness (of) I

This project is made in alignment with the writer believe in the Islamic worldview that human beings are created to worship Allah and to perform righteous deeds (QS. Az-Zāriyāt: 56) and are appointed as khalifah on Earth with the responsibility to maintain balance and prevent destruction (QS. Al-Baqarah: 30). The author consciously understands their role as a servant of Allah, recognizing that engineering knowledge and artificial intelligence are forms of Amanah that must be exercised with accountability and humility.

Remembrance of Allah is maintained throughout the analytical process by acknowledging that the physical laws governing force flow, material behavior, and structural equilibrium represent the divinely ordained order or sunnatullah. Self-awareness is demonstrated through explicit recognition of modeling assumptions, algorithmic bias, and the limitations of AI-assisted reasoning. The author critically reflects that technological advancement devoid of ethical grounding risks harm, whereas technology guided by worship-conscious intent serves benefit to humanity, preserving the environment, and upholding ethics in engineering practice.

2. Intention of the Project Activity

The intention of this project is to develop an AI-assisted engineering framework that enables beneficial, responsible, and sustainable Design for Additive Manufacturing optimization. This intention is explicitly aligned with the Islamic principle that the best of humankind are those who bring the greatest benefit to others. Accordingly, the project seeks to assist engineers in making design decisions that enhance safety, efficiency, environmental impact awareness, and societal value.

The objectives are aligned with higher ethical values: minimizing material waste, reducing energy consumption, preventing structural failure, and supporting transparent human judgment rather than replacing it. By positioning AI as a knowledge assistant and not an autonomous decision-maker, the project preserves human accountability as khalifah. In this context, engineering design is framed as an act of worship performed through excellence, responsibility, and the conscious prevention of harm to people and the Earth.

III. Introduction

Additive manufacturing (AM) enables the fabrication of complex geometries that are difficult to realize using conventional manufacturing processes. However, this geometric freedom often leads to designs that are driven by intuition alone, without sufficient consideration of how forces are transmitted through the structure. As a result, many AM components exhibit inefficient material distribution, unnecessary mass, or localized weaknesses arising from disrupted load paths.

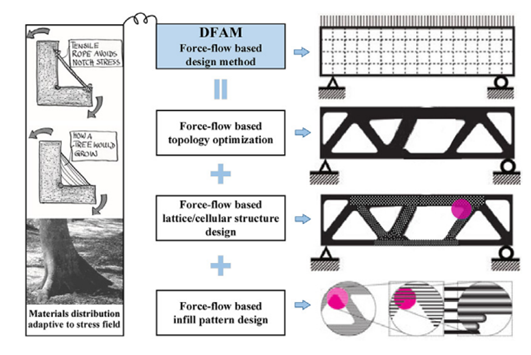

The force-flow perspective provides a framework to address this challenge. In this perspective, a structure is understood as a medium for transmitting forces from points of application to supports through a continuous path. Similar to how natural systems such as tree roots, bones, or branching structures adapt material distribution according to stress fields, force-flow–based design seeks to align geometry with principal stress trajectories. Material is concentrated along dominant load paths (tension, compression, and bending), while regions that do not contribute meaningfully to load transfer are minimized or removed.

Figure 1. Force-flow based design method

In the context of Design for Additive Manufacturing (DfAM), the force-flow perspective is particularly powerful. AM allows internal features such as ribs, trusses, lattices, and graded infill patterns to be shaped in direct response to force transmission. Rather than treating topology optimization, lattice design, and infill generation as separate or purely numerical steps, this project integrates them under a unified force-flow logic. Topology optimization establishes the primary load-bearing skeleton, lattice or cellular structures refine internal material efficiency, and infill patterns further tailor local stiffness—all guided by the same underlying stress field.

This project therefore positions force-flow as the central organizing principle of the AI Knowledge Assistant.

Initial Thinking (about the Problem)

From an engineering perspective, many AM failures originate not from material limits, but from misaligned geometry that interrupts natural load paths. Existing topology optimization tools often function as black boxes, offering limited physical interpretation. Designers, manufacturers, and end-users require solutions that are interpretable, manufacturable, and reliable. This project addresses the root cause by positioning force-flow as the primary organizing principle and using AI as a knowledge integrator rather than a replacement for engineering judgment.

IV. Methodology and Procedures

Idealization

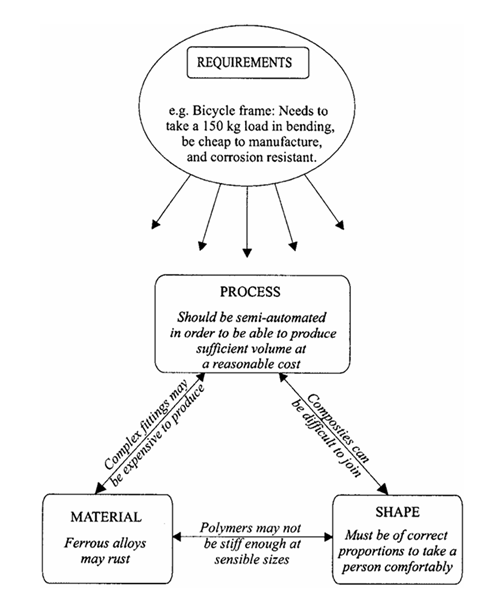

The idealization of the proposed system is based on the classical decomposition of engineering design decisions into three distinct but interrelated areas: material selection, shape definition, and manufacturing process. In this project, these areas are intentionally reformulated to support the objective of Force-Flow–Based DfAM Optimization.

Figure 2. Engineering design decisions

First, material selection is idealized as a constrained choice from a predefined pool of FDM-compatible materials. Each material is characterized by its stiffness, strength, toughness, printability, and anisotropic behavior. The assumption is that early-stage design decisions can be guided effectively using representative linear-elastic properties and qualitative printability knowledge.

Second, shape definition is idealized as a force-driven problem, where geometry is not predefined but emerges from the need to transmit loads efficiently. The shape is conceptualized as a network of load paths that reinforce regions of high stress and eliminate material in low-stress zones, consistent with force-flow principles and DfAM geometric constraints.

Third, the manufacturing process is idealized not as a generic production step, but as printing guidance tightly coupled to both material behavior and force orientation. Process-related assumptions include layer-wise anisotropy, overhang limitations, and minimum feature sizes, which are abstracted into rule-based constraints rather than detailed machine-level simulations.

This idealization preserves physical realism while simplifying complexity, enabling scalable, interpretable, and iterative optimization aligned with the project’s intent.

Instruction (Set)

The operational methodology follows the AI Knowledge Assistant for Force-Flow–Based DfAM Optimization Flowchart, with specific adjustments to material, shape, and process decisions to meet the project objectives:

- User Requirements: Definition of functional intent, operating environment, target weight reduction, and sustainability constraints.

- Functional Load Definition: Specification of load cases, boundary conditions, and safety factors governing structural behavior.

- Force-Flow Analysis (Knowledge Assistant): AI-assisted identification of dominant internal force paths (tension, compression, bending, and shear), prediction of critical stress regions, and classification of low-stress, removable material zones.

- Design Optimization (Shape): Geometry refinement driven by force-flow reasoning, including reinforcement of primary load paths (e.g., ribs, fillets, arches), removal of non-contributing material (e.g., hollowing, lattices, trusses), and application of DfAM rules such as minimum wall thickness, feature size, and overhang constraints. Numerical topology optimization may be applied as a supporting tool.

- Material Selection (FDM Pool): Selection of suitable FDM materials (e.g., PLA, ABS, PETG, Nylon, fiber-reinforced variants) based on required stiffness, strength, environmental resistance, and printability, as informed by force-flow demands.

- Printing Guidance (Adjusted Process): Determination of print orientation to align principal force directions with strong layer axes, along with guidance on perimeters, infill strategy, support placement, and thermal control relevant to force-critical regions.

- Validation and Simulation: Structural verification using FEA to assess stress distribution, deformation, and safety margins against defined requirements.

- Final Output: Delivery of optimized CAD geometry and corresponding printing guidance or profile, ready for fabrication.

The instruction set is inherently iterative, allowing continuous refinement of material, shape, and printing decisions until force-flow continuity, manufacturability, and performance objectives are satisfied.

V. Result and Discussion

The AI knowledge assistant demonstrates improved design coherence by maintaining uninterrupted alignment between loads, geometry, and manufacturing constraints. Designs generated through force-flow reasoning show reduced stress concentrations, smoother load transmission, and higher material efficiency compared to intuition-driven baselines. The interpretability of results enhances designer trust and enables informed trade-offs.

Compared with existing literature on topology optimization, this approach emphasizes physical meaning over numerical abstraction, reducing the risk of non-manufacturable or brittle solutions. The integration of ethical awareness ensures that optimization does not sacrifice safety or sustainability for performance alone. The results highlight that AI, when guided by conscious intention and physical understanding, becomes an amplifier of wisdom rather than a source of opacity.

VI. Conclusion

This project concludes that an AI Knowledge Assistant based on force-flow principles and the DAI5 framework can enhance DfAM optimization. The key contribution lies in unifying technical rigor, interpretability, sustainability, and spiritual awareness into a single coherent methodology.

Recommendations include:

- Extending the framework to nonlinear materials and fatigue loading.

- Integrating real-time manufacturing feedback for adaptive learning.

In closing, this work affirms that engineering excellence is most complete when technical mastery is guided by remembrance of the Creator, ethical responsibility, and service to humanity.

VII. Acknowledgements

The author gratefully acknowledges the support and supervision of Prof. Ir. Ahmad Indra Siswantara, Ph.D. and the support and contributions of colleagues from Department of Mechanical Engineering Universitas Indonesia Masters Program, whose guidance, resources, and encouragement made this work possible.

Youtube Video

https://youtu.be/Vmwg59RLbqY?si=u8ELRshtQrtceA_z

PDF Report Link:

https://drive.google.com/file/d/1KjeoEfvzHMKfC1e1K7iRLjKn-qAgYp12/view?usp=drivesdk